Pour des raisons pratiques, les professionnels ont parfois besoin de transvaser du gaz depuis une grande bouteille vers un contenant plus petit qui leur servira de bouteille de gaz de chantier. Cela permet aux soudeurs et autres utilisateurs d’éviter le port d’une bouteille trop lourde. Les mesures de sécurité sont drastiques, car les dangers d’explosion bien réels. Voici ce qu’il faut savoir.

Les dangers des GPL, gaz propane et butane

Les gaz butane et propane sont des hydrocarbures sous forme gazeuse qui sont liquéfiés pour être conditionnés dans une bouteille de gaz destinée à de multiples utilisations. Ils sont particulièrement inflammables et, mélangés à l’air, la moindre étincelle peut provoquer une explosion. Vous ne devez bien sûr pas fumer, mais vous ne devez pas non plus utiliser de téléphone portable à proximité de votre chantier. Les GPL sont aussi sensibles aux changements de température et se dilatent lorsqu’elle augmente.

Les gaz butane et propane sont des hydrocarbures sous forme gazeuse qui sont liquéfiés pour être conditionnés dans une bouteille de gaz destinée à de multiples utilisations. Ils sont particulièrement inflammables et, mélangés à l’air, la moindre étincelle peut provoquer une explosion. Vous ne devez bien sûr pas fumer, mais vous ne devez pas non plus utiliser de téléphone portable à proximité de votre chantier. Les GPL sont aussi sensibles aux changements de température et se dilatent lorsqu’elle augmente.

Voilà pourquoi vous devez effectuer toutes vos manipulations en plein air, en l’absence de toute étincelle ou flamme, et toujours prévoir un extincteur à portée de main. Vous devez utiliser des gants et des lunettes de protection, car l’évaporation du gaz peut engendrer des brûlures.

Comment remplir votre bouteille avec un raccord de transvasement Express

Le gaz propane ou butane ne doit être transvasé que depuis une bouteille de 13 kilos nets. Vous ne devez jamais remplir complètement votre bouteille de chantier, afin de tenir compte de la dilatation lorsque la température monte. Si vous l’avez trop remplie par inadvertance, ouvrez le robinet en plein air, afin d’évacuer ce surplus.

Vous ne devez jamais raccorder les deux bouteilles directement, mais utiliser un raccord de transvasement, muni d’un joint à chaque extrémité. Serrez fermement les écrous à la main. Vous devez vérifier que votre montage est parfaitement étanche en pulvérisant un mélange savonneux. Vérifiez sur chaque bouteille les robinets, leur volant et leur sortie.

Commencez par ouvrir de robinet de la petite bouteille de chantier, puis ouvrez lentement celui de la grande bouteille. La bouteille de chantier va se remplir lentement et vous devez entendre le bruit du transvasement. Attention de ne pas ouvrir trop rapidement le robinet de la grande bouteille, sinon, le remplissage risque d’être insuffisant. Le cas échéant, refermez-le puis ouvrez-le à nouveau plus lentement.

Dévissez ensuite la purge de la petite bouteille à l’aide d’un tournevis. Vous constatez qu’un peu de gaz s’échappe par le filetage. Lorsque la bouteille est pleine, le gaz commence à former des gouttelettes. Revissez alors la purge avec votre tournevis, sans forcer.

En cas de limitateur de débit

Il se peut que votre bouteille de gaz soit équipée d’un limitateur de débit. Vérifiez en retirant le bouchon de sécurité : c’est le cas si le débit de gaz est presque immédiatement ralenti lorsque vous ouvrez le robinet. Dans ce cas, vous devez ouvrir très peu votre bouteille de 13 kilos, c’est-à-dire de seulement un quart ou un huitième de tour. Le remplissage sera seulement un peu plus lent.

Une fois l’opération terminée, refermez les robinets des bouteilles, puis retirez le raccord de transvasement.

La masse totale de la bouteille pleine ne doit jamais dépasser 5,7 kilos. Vous devez sinon évacuer le gaz excédant, toujours en plein air et loin de toute flamme ou étincelle.

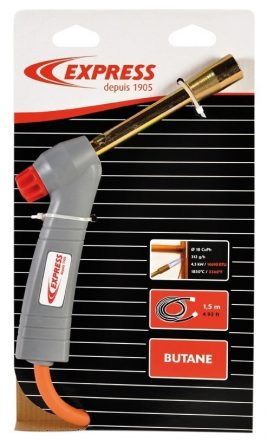

Produits associés

Products associated with this item available on express

-

25,70€ HT

Standard plumbing torch Cat. No. 5100

Plumbing professional torch Cat. No. 5100, a standard that will render many services...