Le principal objectif pour réussir vos travaux de brasure et de soudure est d’atteindre la meilleure performance mécanique possible. La température des points de fusion de chacun des matériaux que vous utilisez fait partie des éléments essentiels à connaître pour bien traiter vos éléments de base, ainsi que votre métal d’apport, et utiliser les bonnes températures avec votre fer à souder.

Qu’est-ce que le point de fusion en soudure et en brasure ?

Le point de fusion d’un matériau correspond à la température à partir de laquelle il passe de l’état solide à l’état liquide.

Vous devez considérer la pureté des matériaux que vous voulez souder ou braser. La liste des points de fusion donne les températures pour des métaux purs. Dès lors que vous utilisez des alliages, vous devez prendre en compte les différents matériaux qui le composent et qui possèdent bien souvent des points de fusion différents.

Il est difficile de déterminer le point de fusion d’un alliage, car il ne suffit pas de faire une moyenne entre les différents composants, d’autant que les proportions varient d’un alliage à l’autre. La métallurgie permet, en établissant des diagrammes de phase, de connaître les plages utilisables pour les brasures. Ces valeurs sont précisées sur les produits que vous achetez.

La différence entre soudure et brasure

Brasure et soudure sont deux opérations différentes.

La soudure

Pour effectuer une soudure, vous chauffez vos matériaux de base, ainsi que le métal d’apport dans la plupart des procédés, jusqu’à atteindre le point de fusion. Vous devez alors appliquer la température du point de fusion des métaux que vous soudez entre eux.

Il est donc préférable que les différents composants destinés à la soudure possèdent des points de fusion proches les uns des autres. Notez que de façon impropre, il est qualifié de soudure des actions qui devraient être appelées “brasures” comme la soudure étain par exemple. Il s’agit d’habitudes de langage des utilisateurs qu’il n’est pas opportun de relever au quotidien.

La brasure

Dans le cadre de la brasure, vous ne faites pas fusionner vos métaux de base, mais seulement votre métal d’apport. Il est donc impératif que le point de fusion de votre métal d’apport soit inférieur à celui des métaux que vous envisagez d’assembler.

Vous pouvez utiliser le brasage tendre ou le brasage dur. Avec le premier, le point de fusion du métal d’apport est inférieur à 450 °C, pour le second, la température à atteindre est comprise entre 600 °C à 1000 °C.

Pour le brasage tendre, le métal d’apport le plus souvent choisi est l’étain qui possède le point de fusion le moins élevé des métaux d’apport les plus couramment utilisés.

Lorsque vous effectuez une brasure, votre métal d’apport doit atteindre son point de fusion pour passer à la phase liquide. Une fois mis au contact des deux pièces à assembler, il va se répandre et se diffuser par capillarité, c’est-à-dire qu’il s’insinue comme au travers d’un réseau de minuscules canaux sur les métaux de base.

Pour qu’il puisse se diffuser sur l’un et l’autre des deux éléments à braser, ceux-ci doivent être parfaitement préparés et nettoyés. Toute marque de graisse ou toute aspérité empêche la progression du métal d’apport et fragilise la brasure.

Pour bien préparer vos surfaces une fois qu’elles sont nettoyées et dégraissées, vous devez les frotter avec une surface abrasive, comme la toile émeri, qui va créer de minuscules rayures qui favorisent la progression du métal d’apport et vous garantissent une brasure plus robuste et durable.

Les points de fusion des principaux métaux utilisés en soudure ou en brasure

|

Matériaux |

Température de fusion |

|

Étain |

232 °C |

|

Plomb |

327 °C |

|

Zinc |

419 °C |

|

Aluminium (pur) |

660 °C |

|

Bronze |

890 °C |

|

Laiton |

900 °C |

|

Argent |

961 °C |

|

Or |

1 064 °C |

|

Cuivre |

1 083 °C |

|

Inox |

1 400 °C |

|

Acier |

1 450 °C |

|

Nickel |

1 455 °C |

|

Fer (pur) |

1 553 °C |

|

Palladium |

1 555 °C |

|

Platine |

1 772 °C |

|

Fonte |

1 820 °C |

| Aluminium brut (allumine) |

1 835 °C |

Produits associés

Products associated with this item available on express

-

61,87€ HT

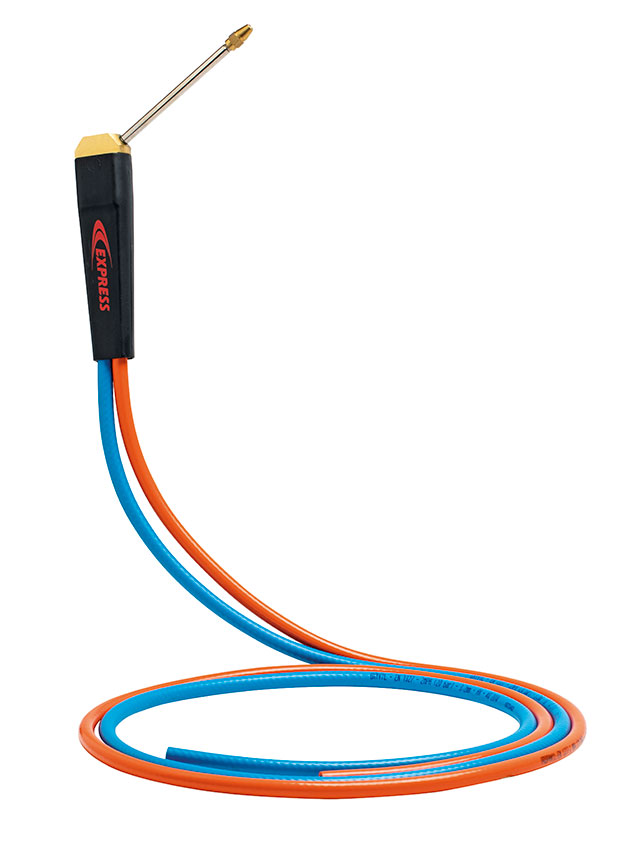

Handle and pre-mounted hoses Cat. No. 2991 for the oxy-gas set Oxy-Kid 2901

This handle and pre-mounted hoses Cat. No. 2991 are designed for use exclusively... -

43,45€ HT

Oxygen valve Cat. No. 2993 for the Oxy-gas set Oxy-Kid 2901

The brass oxygen valve Cat. No. 2993, with flow limiter, is designed for the Express... -

11,07€ HT

Pickling paste for brazing Cat. No. GE6GFA-50

The boric acid-free pickling paste for CuPh Ag brazing cat. No. GEGFA-50 (100D) is... -

29,02€ HT

Soldering flux Cat. No. GE6GFA-200

The boric acid-free pickling paste for CuPh Ag brazing Cat. No. GEGFA-200 is...