Brasure et soudure sont deux techniques différentes. Dans le premier cas, vous devez apporter un troisième élément, c’est-à-dire un autre métal d’apport qui va faire le joint, tandis que dans le second cas, les deux pièces se suffisent, car elles vont s’amalgamer. Voici dans le détail les différences entre ces deux méthodes.

Brasure versus soudure

Lorsque vous procédez à une soudure entre deux pièces de métal, en fondant sous la chaleur, elles créent des liaisons atomiques entre elles qui leur permettent de s’unifier parfaitement.

Lorsque vous procédez à une brasure, vos deux pièces de métal ne créent pas de liaisons atomiques, ce qui vous oblige à apporter un autre métal qui va faire la jonction entre les deux.

Chaque technique possède ses avantages et ses inconvénients. La soudure produit un cordon au niveau du joint qui est épais et irrégulier, ce qui n’est guère esthétique. Si cette soudure est apparente, vous devrez passer du temps sur les finitions pour qu’elle devienne la plus discrète possible.

Un joint brasé en revanche est tout à fait lisse, ce qui garantit une finition naturelle beaucoup plus esthétique (et économique, puisque vous n’avez pas à y passer du temps).

La soudure

Ceci peut poser un problème lorsque vous souhaitez assembler deux pièces dont les températures de point de fusion sont différentes, par exemple entre le cuivre (point de fusion à 1 083 °C) et l’acier (point de fusion à 1 370 °C).

Le résultat d’une soudure est d’une solidité à toute épreuve, c’est pourquoi elle peut être utilisée pour des travaux d’ampleur, comment dans le bâtiment, la construction, les chemins de fer, les pipelines, etc.

La brasure

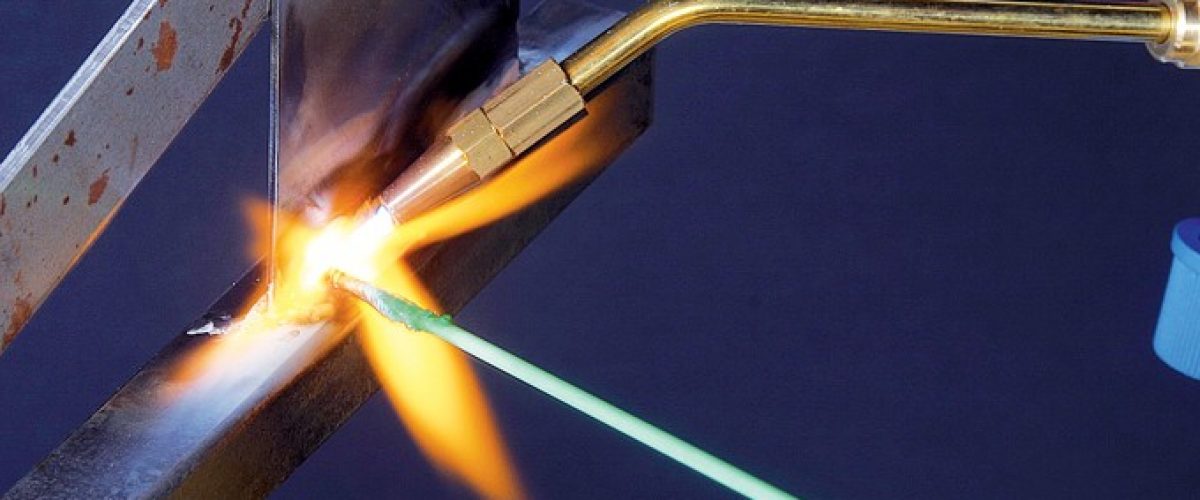

Pour utiliser cette technique, vous chauffez d’abord les deux pièces à souder et apportez ensuite votre métal d’apport qui va fondre à leur contact (et non sous la chaleur de la flamme de votre fer à souder). Au fur et à mesure qu’il s’amollit, le métal d’apport se diffuse par capillarité. En refroidissant, les deux pièces deviennent indissociables.

Vous pouvez utiliser de l’étain – qui peut être éventuellement associé à du nickel – comme métal d’apport. Le plomb était autrefois aussi beaucoup utilisé, mais son usage a été restreint, et même banni pour toutes les canalisations d’eau potable, car il dégage des particules hautement toxiques pour notre organisme.

La brasure s’applique à toutes sortes de métaux, comme le cuivre ou l’acier, ainsi que pour des composants non métalliques, comme le graphite, l’alumine, le carbure de tungstène et même le diamant. Elle est généralement réservée à des travaux plus fins que la soudure : électricité, composants électroniques, aérospatial, chauffage, climatisation, automobile, etc.

La brasure permet de conserver les propriétés physiques des métaux, puisqu’ils ne sont pas eux-mêmes fondus. Elle prévient également tous les risques de déformation des métaux (que l’on appelle gauchissement).

Produits associés

-

61,11€ HT

Multifunction Lamp’ Express blowlamp 531

Blowlamp with enveloping flame Cercoflam burner, sharp tip flame burner and flat...

Products associated with this item available on express

-

57,20€ HT

Lamp’ Express blowlamp for plumbers Cat. No. 525

Blowlamp with an adaptable accessory Cercoflam burner. Hard brazing in less than...